This series of wood line sander uses sanding head sanding components, which can be arranged and combined in different numbers to meet the demand.

It can also be equipped with automatic feeding device to achieve mass feeding.

This part is a sponge wheel abrasive belt component, which can be used for sand plane and profiled surface, and has channeling function. It can sanding wood surface with high efficiency and quality. Sand head can adjust belt speed independently by frequency conversion.

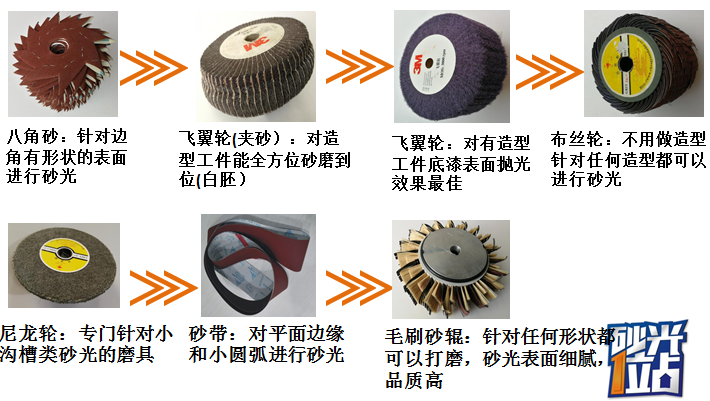

The grinding head is matched with the universal standard grinding wheels in the world. It can install brush rollers, octagonal sand, grinding wheels and other abrasives. It has the advantages of simple operation, easy replacement of abrasive belts, convenient abrasive material, automatic expansion function to protect the head and tail of the workpiece, and automatic compensation by using grinding wheels.

Characteristic:

It has good universality for processing surface, strong abrasive matching, and can grind any special-shaped surface.

Sponge wheel grinding head: The structure of circular abrasive belt is installed outside the sponge wheel, which has high quality sanding effect on the edge plane and small arc. It can also open a small groove on the sponge wheel (below R5) to effectively meet the sanding requirements. Free Selection of Belt Number

The contact with the board is adjusted by three-dimensional advance and retreat adjustment of the column. The best case is that the abrasive belt is just combined with the board. It has automatic forward and backward control system and automatic compensation system.

Linear Sander Machine description of the process:

Mechanical features:

According to different process requirements, various sand heads are arranged and disposed freely.

The sand head can be adjusted from - 90 +90, which is suitable for straight line profiling sanding.

Sand head with automatic compensation function, induction forward and backward function, to ensure that the head and tail of the workpiece is not sand pierced, not sand round;

Pneumatic pressing material is used for pressing material, spring load, reliable pressing material, no damage to the workpiece;

PLC precise control, easy to adjust;

Different power motors and abrasives with different shapes and functions can be selected according to different shapes.

Single sand head can install more than four kinds of abrasives.

Sand head has independent swing function.

Sand head has independent automatic compensation and automatic feeding function.

Technical specification:

| Model | SLQ-W6 | SLQ-W8 |

| Right-angle thickness of workpiece feeding | 30 | 30 |

| Minimum length of workpiece feeding | 450mm | 450mm |

| Maximum width of workpiece feeding | 180mm | 180mm |

| Feeding speed | 10~35m/min | 10~35m/min |

| Profile wheel size(Inner diameter x thickness) | 76x100 | 76x100 |

| Maximum effective grinding width of grinding frame | 60mm | 60mm |

| Circumference:

Maximum width: | 960mm 100mm | 960mm 100mm |

| Maximum effective width of grinding head | 65mm | 65mm |

| The inclinable angle of sand head | ±90° | ±90° |

| Frame length | 4 m | 6 m |

| Total power of motor | 8.21kw | 10.8kw |

| Shape size (mm) | 4000x1500x1500 | 5700x1500x1500 |

| Net weight | 1300kg | 1900kg |